After working as a bookbinder from the age of 15, Roy Shaddock opens his own bindery in Covent Garden, London. He is joined, part time by his wife Sylvie, who has also worked in the industry since leaving school.

Covent Garden undergoes extensive redevelopment and so Roy moves the company to a new site in Bethnal Green.

The company is renamed ‘RS Bookbinders’, ‘R’ for Roy and ‘S’ for Sylvie.

Graham joins his father at RS with a view to taking over when Roy retires.

The bindery is expanding its services and becomes well known for producing superior leather accounts ledgers, offering bespoke hand marbled endpapers and gilt or marbled edging.

Graham takes over the running of the business. Roy continues to work at RS on a part-time basis.

Graham has big ideas and moves the company to a much larger premises, just down the road in Cudworth street, Bethnal Green.

The company’s reputation for exceptional leather work grows and they are approached by several high-end retail clients to produce large quantities of leather-bound books and photo albums.

Roy decides the time is right for retirement.

The building in Cudworth street is sold and developed into flats, but Graham ensures that the spirit of the company lives on, as the development is named “Bookbinders Court”

Graham moves the company, this time to Hockley in Essex.

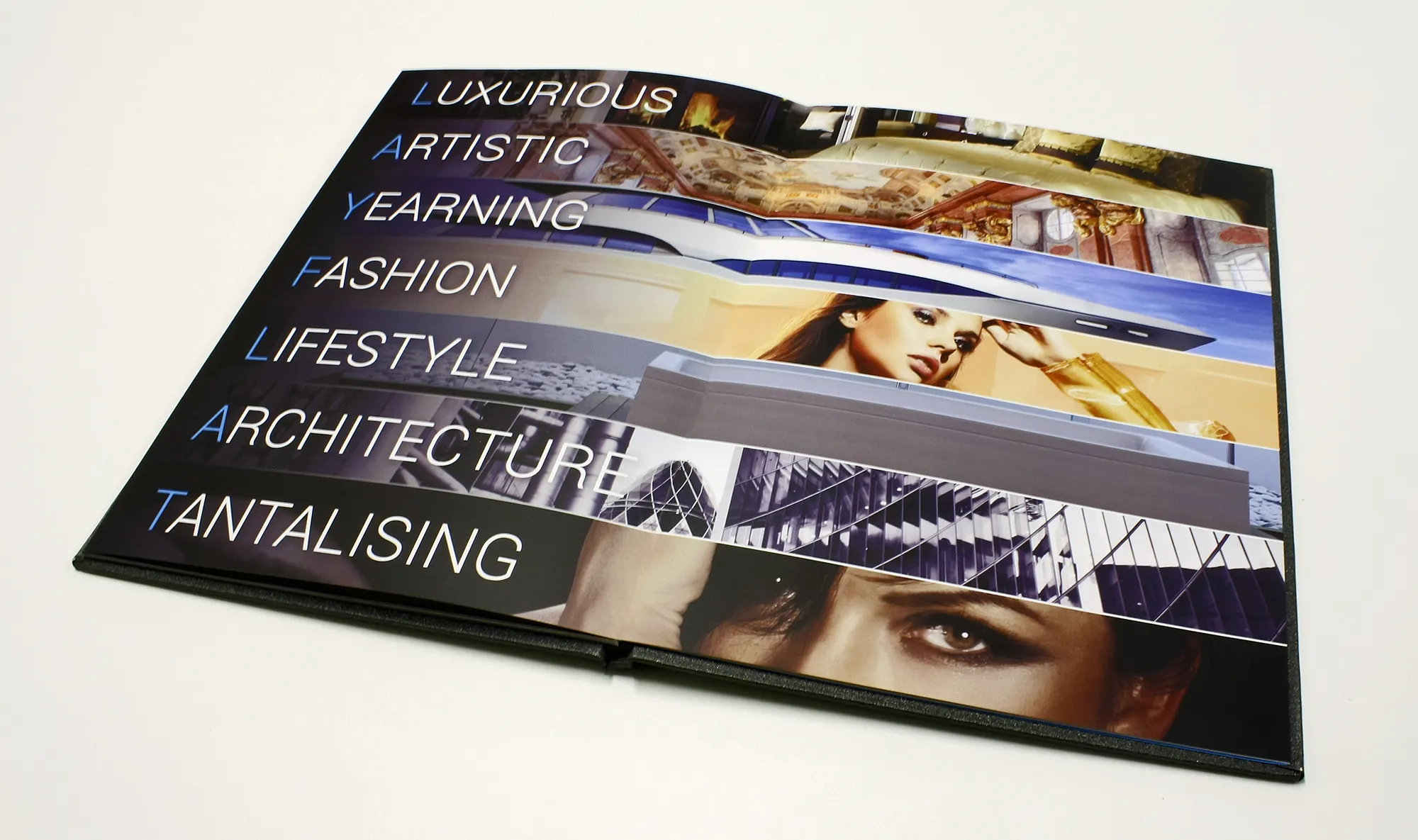

We are one of the first companies in the UK to invest in a “layflat” machine and introduce layflat binding to the UK market.

With its large image spreads and seamless panoramic views, it is the perfect format to showcase the projects and designs from a diverse range of industries – property, architecture and design; to name a few.

This proved to be a huge boon to the company as it brought us to the attention of a whole new portfolio of high-end clientele.

We soon run out of space and move to our current location in Rochford, Essex.

This move allows us to invest in more semi-automated machinery allowing us to produce ‘larger quantities’ without losing the handmade, bespoke finishes.

As demand for our high-end box making grows, we invest in semi-automatic box making equipment. This allows us to offer much larger production runs and competitive pricing.

Today, our passion for our work and our commitment to quality are as strong as ever.

We continue to invest in both our workforce and in new technology. This enables us to continue working to the highest standards and bring the creative concepts of our clients to life.